Active Compression Garments

Novel type of upper-body compression garments for deep pressure therapy and haptic communications.

As a graduate research assistant in the Wearable Technology Lab, I worked in a small team to develop an innovative form of compression garments for nearly 2 years.

Functioning as the project’s apparel design lead, I performed most of the garment design and construction (patterning, sewing, & stitching), as well as much of the apparel-hardware integration. With no prior education or training in apparel design or wearable technology, I demonstrated my adaptability and aptitude for quick learning, as I swiftly acquired and applied necessary skills and knowledge in functional apparel design, garment construction, anthropometrics, and electrical engineering.

My educational background in my psychology also helped me conduct several human subject tests and analyze data with my team during this extensive iterative design process, and these prototype designs and human subject testing results have been published or showcased in several conferences.

Organization: Wearable Tech Lab @ University of Minnesota

PI: Dr. Brad Holschuh (NSF grant #1656995)

Timeline: Fall 2017 - Spring 2019 (4 semesters)

Link to Project: https://design.umn.edu/wearable-technology-lab/research/computer-mediated-compression

Tasks & Responsibilities: Design & construct the soft goods and integrate required hardware for the upper-body compression garment prototypes. Collaborate in recruiting participants, conducting usability studies, and analyzing study results.

Platforms: Physical garment prototypes

Collaborators: Esther Foo, Simon Ozbek, & Crystal Compton

Background & Motivation

With its similarity to a hugging sensation, on-body compression is known to alleviate anxiety and stress, and is widely used as a method of therapeutic intervention (most notably, ‘deep pressure therapy’ for autism spectrum disorders).

While there are many types of compressive wearables in the market (i.e., inflatable, weighted, or elastic), these conventional designs exhibit a range of inherent usability issues.

Weighted garments can be heavy and bulky, with limited compressive pressure provided

Elastic garments, with static pressure profile, can be difficult to don/doff

Inflatables can also be bulky and inflating/deflating may be a hassle

To overcome these limitations, this project focused on designing and developing a new type of compression garment that can deliver computer-mediated, remotely-controllable compression on body, using shape memory alloy (SMA) materials.

SMA springs in action

V1: Passive-compression prototype

Currently, deep pressure therapy (DTP) is mostly based on anecdotal evidence, and there has been little documented evidence on optimal compression profiles for users. It was hence necessary to begin the project by researching exactly what location, intensity, and duration of compression correspond to optimal user experiences.

To investigate subjective experiences of on-body compression, we constructed a low-fidelity prototype (in the form of a vest made of woven canvas fabric) and conducted a user study. Compression was passively administered and adjusted (with Velcro strips attached/detached by hand), to create a wizard-of-oz testing experience.

Photos of V1 prototype (front/side/back)

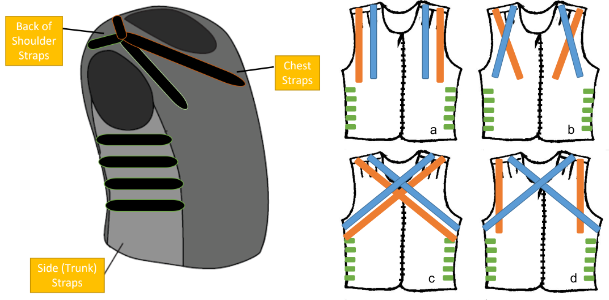

Schematic of the V1 prototype (left) and test conditions used (right)

In this preliminary study, 5 participants (2M/3F) rated their subjective comfort and emotional states to various compression profiles. Users generally felt positive and calm with the garment-administered upper-body compression, and they wished for more compression on the lower back & sides for better support, while wanting more flexibility on the chest & front for respiration. Feedback also included needs for a less stiff garment with a longer torso length and a more tapered compression profile.

V2: Active-compression prototype

Armed with the knowledge from the first design iteration and associated user study, we went onto creating and testing the medium-fidelity prototype that uses SMA coils to achieve active, controllable compression.

We went through a period of trial and error and bench-testing to work out an optimal design mechanism for integrating active materials in a garment form, as it was an unconventional challenge to build a garment that dynamically changes its dimensions while wearing. Because the SMA activation required resistance heating from applied electric current, the design had to also sufficiently insulate the wearer while also generating a desired amount and even distribution of compression.

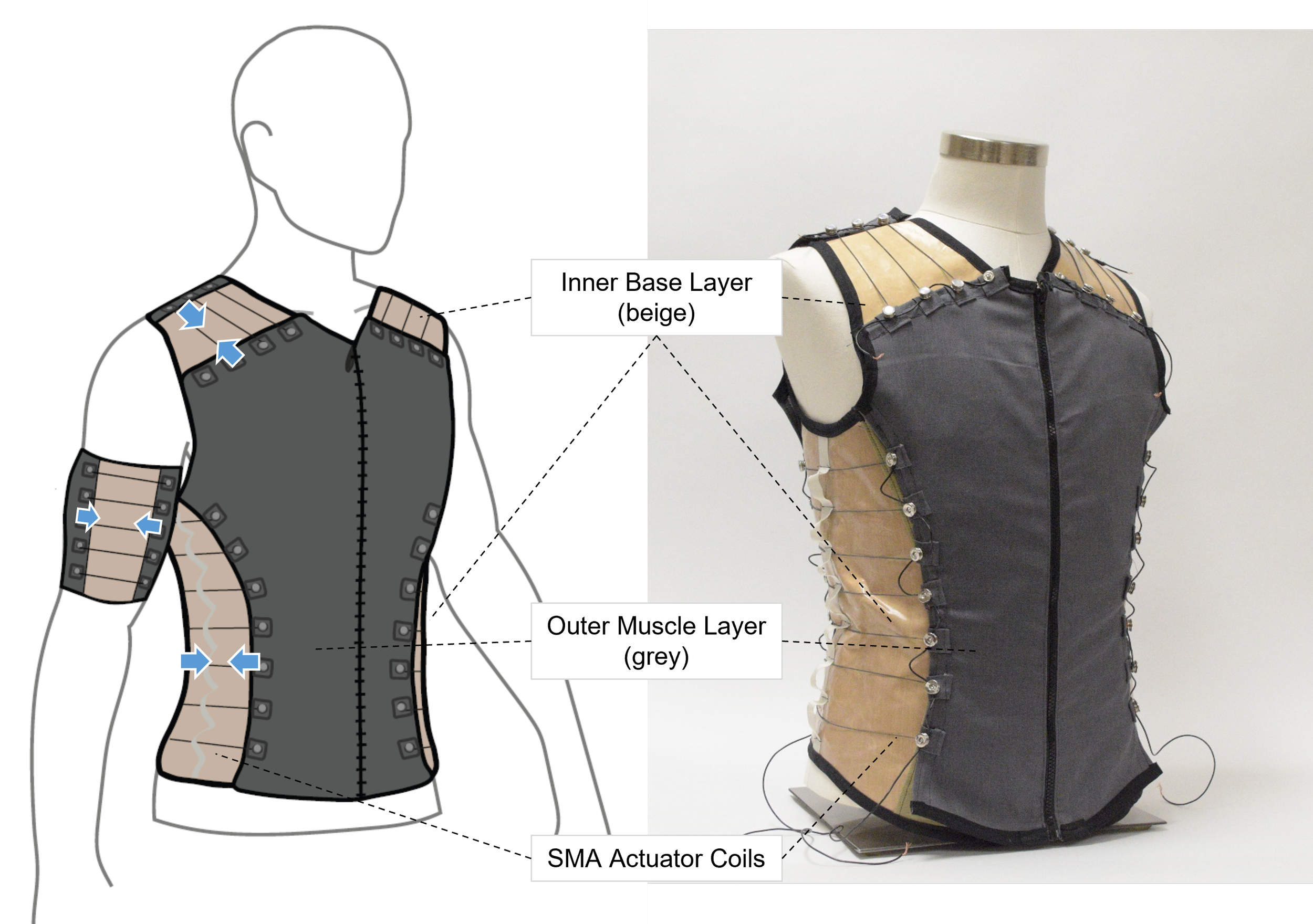

I then patterned and constructed our first active-compression prototype (size: Male S), which uses a dual-layer mechanism (a smooth-surfaced ‘base’ layer on which a ‘muscle’ layer constricts around the torso) to create a circumferential pressure on the body.

Photos of V2 prototype (front/side/back)

To test this prototype, we carried out an exploratory user study with 8 male participants to understand their subjective experiences with the novel SMA-generated compression scheme. Through psychometric surveys, think-aloud methods, and qualitative interviews, we confirmed that the design was overall perceived to be comfortable and calming for most users, but we also identified areas for improvement regarding the fabric choice and pressure distribution.

V3: Remotely-controlled & battery-powered prototype

Using insights and feedback from the previous iterations, we designed and constructed a higher-fidelity prototype with improved adjustability, mobility, and comfort of the garment.

Shielded SMA coil in action

Female (left) and male (right) garments in construction

In this version of the prototype, we were able to make the garments less stiff and more flexible by using thinner insulation fabrics and shielded actuator coils. Unlike V2, which was operated with a wired DC power supply, the actuators in V3 were battery-powered and remotely controllable via Bluetooth; I worked closely with my team to successfully incorporate necessary electric components and batteries in the final garment design. In addition, to better accommodate the sex differences in sizing & fit, separate male and female garments were designed and constructed in this prototype iteration.

Photos of V3 prototype: armbands (left), male (middle) and female (right) garments

Female garment, with integrated battery & electronic components

To better understand the subjective experiences to the more nuanced compression parameters enabled in this iteration, we carried out a within-subjects experimental study with 17 participants (8M/9F) using this prototype. We found considerable gender differences as well as individual differences in the perception and preference of the varying compression intensities and locations on the upper body, suggesting the need for an even better garment fit & sizing system and better customizability. Many users also indicated that their perception and preferences of compression would considerably depend on the use scenario of the garment, hinting at potential applications of the compression garment beyond therapeutic uses (i.e., affective or communicative haptics) and highlighting the importance of context in user experiences.

In conclusion…

What I learned

Through hands-on experience I have learned a lot about advanced apparel design, anthropometrics/sizing/fit, and electrical engineering for researching and developing wearable technology devices. By carrying out the iterative design process firsthand, I also learned how to conduct usability studies, analyze user feedback, and troubleshooting problems by finding creative design solutions.

Were there any insights from user research that surprised you?

I was pleasantly surprised that the SMA-generated compression was well-accepted by most users, and specifically that many people welcomed the sensation of tight compression around the lower torso and back as being supportive. I was also intrigued by some of the users feeling more stimulated (rather than calm) with compression.

What was the most challenging thing about this project and how did you overcome it?

The most difficult challenge was figuring out a way to incorporate SMA coils, which need to be securely connected to electric wires and need to be insulated from human skin, into a garment form that actively changes its shape and size while in usage, because it is a novel concept. I overcame the challenge by quickly mastering necessary garment design skills to test out ideas for what might work and consulting other colleagues about electronic engineering when necessary.

What part of the design process did you particularly enjoy?

It was fun to find creative, novel design solutions to an existing usability problem, and witnessing the prototypes working and being well accepted by users was extremely rewarding.